The Robo-One committee in Japan has announced the dates and venue for the 22nd Robo-One Competition, and the 6th Robo-One Light:

Feb. 23-24, 2013

Startup company Formlabs has run a successful Kickstarter campaign (in 2.5 hours!) to fund development of a entry in the home/office 3D printer market. The FORM 1 3D printer is the first home 3D printer I’ve seen that uses a stereolithography process — that is, it uses an ultraviolet laser in a vat of resin to cure your part one layer at a time.

Startup company Formlabs has run a successful Kickstarter campaign (in 2.5 hours!) to fund development of a entry in the home/office 3D printer market. The FORM 1 3D printer is the first home 3D printer I’ve seen that uses a stereolithography process — that is, it uses an ultraviolet laser in a vat of resin to cure your part one layer at a time.

The Kickstarter is closed, but the price of the FORM 1 is expected to be slightly more than the Makerbot Replicator 2, i.e., somewhere in the $2500 range. The vertical resolution of the FORM 1, 25 microns, is better than Makerbot’s 100 microns; and the XY feature size (300 microns) is also slightly better (Makerbot’s nozzle diameter is 400 microns). So we’re looking at a slightly more expensive printer, with slightly higher resolution all around, but using a completely different process. (See our earlier comparison of Makerbot and Cubify).

The FORM 1 is expected to start shipping to Kickstarter participants in February. Personally, I’m not sure having a vat of expensive resin is better than having a spool of cheap filament, even if the resolution does come out a bit higher. But I’m sure of this: more options are better for us users. 3D printing is not only here to stay; it’s improving exponentially.

All right, this Hack a Day post (originally from Make) is amazing. Japanese papercraft maker Kikousya has built a full wind-up walking humanoid entirely out of paper, rubber bands, tape, and glue. This isn’t like your typical wind-up toy where the support footprint of the two feet actually overlap — this thing has perfectly reasonable feet, and it walks by shifting its weight, just like you and me. (Jump to 3:10 or so in the build video to see it actually walk.)

All right, this Hack a Day post (originally from Make) is amazing. Japanese papercraft maker Kikousya has built a full wind-up walking humanoid entirely out of paper, rubber bands, tape, and glue. This isn’t like your typical wind-up toy where the support footprint of the two feet actually overlap — this thing has perfectly reasonable feet, and it walks by shifting its weight, just like you and me. (Jump to 3:10 or so in the build video to see it actually walk.)

There is only one (wind-up) motor, so if you were ever looking for ideas for a minimal (one-servo?) biped design, you could certainly get some here.

But watch that build video. The intricacy of this thing is amazing.

…This must be the sort of thing people do when they don’t have kids.

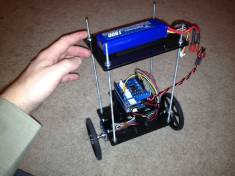

This post at Hack a Day is well worth a look. Robotics hobbyist Willy Wampa has built a very impressive 2-wheel (Segway-style) balancing robot, using common components: an Arduino with a motor shield, an IMU from SparkFun; and chassis and motors from Pololu. He’s tuned his PID loop (based on open-source code) perfectly, as you can see in the video in the post; the thing looks rock-solid, even when it starts and stops, and even running on carpet.

This post at Hack a Day is well worth a look. Robotics hobbyist Willy Wampa has built a very impressive 2-wheel (Segway-style) balancing robot, using common components: an Arduino with a motor shield, an IMU from SparkFun; and chassis and motors from Pololu. He’s tuned his PID loop (based on open-source code) perfectly, as you can see in the video in the post; the thing looks rock-solid, even when it starts and stops, and even running on carpet.

I’ve always felt that before tackling dynamic balancing in bipeds, building a mini-Segway would be a good warm-up. I confess that I haven’t gotten around to this yet, but when I do, you can believe I’m going to look to Wampa’s robot for inspiration.

![]() Georgia Tech (through Coursera) is offering a juicy-looking 8-week course titled “Control of Mobile Robots.” They start with collision avoidance in teams of wheeled robots, and work their way up to full biped locomotion.

Georgia Tech (through Coursera) is offering a juicy-looking 8-week course titled “Control of Mobile Robots.” They start with collision avoidance in teams of wheeled robots, and work their way up to full biped locomotion.

At 5-7 hours of work per week, driven by 10-minute video lectures, it shouldn’t put too much strain on your schedule. And you can’t argue with a price tag of “free.”

The next session begins January 28th. Check it out, and get yourself a firm background in control theory so you can build a better biped!

Makerbot recently announced their new Replicator 2 desktop 3D printer. As 3D printers are wonderful for making brackets and shells for humanoid robots, I figure it’s topical enough to compare the two best low-cost, high-quality printers now on the market: the Makerbot Replicator 2, and the Cubify Cube 3D. Both use an additive printing process, by melting a plastic filament and extruding it through a nozzle to build up your part in layers. But they differ a bit in the details.

The brains of most humanoid robots are either an embedded Linux board, such as the Gumstix (or, I predict, the Raspberry Pi); or an ATmega328 (or its smaller cousin, the ATmega168). The former offers a full Linux environment, running at 600-800 MHz, with all the on-board dev tools, file management, and other trappings that implies. The latter offers just a chip, running at 16 MHz or so, with no standard OS at all. You might install a tiny RTOS, or you might put in an Arduino bootloader, or you might just bang out code in C on your desktop and stuff it onto the chip.

Between these two extremes, there hasn’t been much else… until now.

I’ve met a lot of people who want to get into the hobby, but aren’t sure where to start. There are many different kits (and non-kits!) to choose from. Choosing something too advanced for your time and skill constraints leads to frustration and disillusionment. But a robot too simple or limited can become an expensive dust collector.

So, to help clarify and categorize the options available, I’ve developed this framework, dividing humanoid robots into “levels” according to the amount of skill and effort involved.

Read more…

An article in IEEE Spectrum introduces the new “Baxter” humanoid industrial robot from Rethink Robotics. Rethink is a new company founded by famed MIT roboticist Rodney Brooks, who feels that Baxter is something truly revolutionary: an industrial robot that is simple, safe, easy to use, and affordable (about $22,000, which is quite cheap as industrial robots go).

Several features of the Baxter robot are of particular interest to robot hobbyists. First, take note of the robot’s compliance, or ability to sense and react to the forces being applied to its joints. Baxter accomplishes this through series elastic actuators — that is, each motor is connected to a spring, and the spring actually drives the joint. However, with sufficiently smart servos and programming, you can do something very similar without springs. A good servo will report its torque and position, and if these are not what you expect for the current task, then some external force is acting on it, and you can respond accordingly. The trivial use of this is “pose capture,” where you have some or all servos go limp, you manipulate the robot into the pose you want, and then the software captures this as a pose it can replay later. But more sophisticated uses are also possible.

The other notable feature is that the whole thing runs on Linux and ROS, the open-source Robot Operating System. ROS seems to be really taking off, and with great new embedded Linux platforms like the Raspberry Pi becoming available, there are fewer and fewer reasons not to jump on board.

Check out the article, think about what lessons we can apply to our own robots, and share your thoughts below!

The 21st Robo-One competition was recently held in Japan. It’s a big event, for which entrants must qualify by first running a foot race. Sufficiently agile bots then pair off in a big elimination tournament.

You can see the complete results here, where the winner of each match is shown with a yellow line. Most of the robot names are written in katakana, the phonetic writing system used mainly for foreign words, so with this introduction, you should be able to decipher them.

The final match came down to Cortejyu Miharusu vs. Garoo. Here’s a great video of this final match, thanks to Robots-Dreams:

And the winner is… Garoo! This is Garoo’s third win (read more about its second win here), and one of the few Robo-One bots built by a woman. I’ll try to dig up more details about this great bot and its builder for future posts.